|

| Child Labor in the Carpet Industry |

The Center for the Improvement of Working Conditions & Environment (CIWCE) 'works to promote occupational safety and health in Pakistan, particularly for the vulnerable and marginalized workers, particularly working children.'

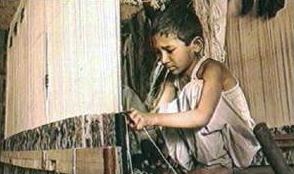

A key focus for CIWCE is the series of problems associated with carpet weaving, which is a very labor-intensive task performed by both adults and children, mostly all females.

Because of the construction of the typical, older-model carpet weave, adults found it particularly difficult to use the loom as it required users to maintain a constant squatting position on the floor.

In addition to being cumbersome for a full-sized adult, it also resulted in many back and leg deformities in those who sat in this position for the extended periods of time the work entailed.

Consequently, carpet weaving became a prominent occupation for children. In the province of Punjab, alone, more than 150,000 children weave carpet, and families, in turn, rely on these children for income and survival.

Having performed many research studies on child labor that in turn provided the foundation for work to end such practices, CIWCE took it upon itself to improve working conditions for carpet weave laborers, and to facilitate the removal of children from this workforce.

Under the direction of Saeed Awan, CIWCE developed a more ergonomic, and adult-friendly loom. With the new loom, carpet weavers have the option to sit on a chair or to stand, making it much easier for adults to weave, as they no longer have to work in the tiresome squatting position. This new technology simultaneously improves incomes, and allows children the potential to leave this workforce, and perhaps even to return to school.

In addition to helping reduce the deformities and physical problems produced by the older models, the new loom also eliminates the risk of severe facial injury, which so often occurred during winding of the older chain-wound machines.

Saeed Awan and the Center for the Improvement of Working Conditions & Environment were honored with the 2005 Tech Museum Knight Ridder Equality Award, one of only 5 key prize awards offered. The Tech Museum Awards honor "innovators using technology to make the world safer and healthier, more prosperous and just."

|

| Saeed Awan |

Can you tell us about how and why you started your project?

Our work revolves around improving the working conditions within the factory sector, but for the last 15 years I have been working, personally, along with my colleagues on [behalf of] the vulnerable and very marginalized segments of the workforce, including women and children.

This particular project was actually focused on the children whose health was being affected by working in the carpet industry. We found out that as the children grow up, their ability to earn a decent living decreases dramatically, mainly due to the poor design of the loom.... they have to sit in a very awkward position, with very awkward posture, and then as they grow up, their limbs become distorted, and they have respiratory and [a variety of] other problems. Then, when they become adults, they rely on their children.

So what we did is to produce an ergonomic loom which does not cause the kinds of problems that traditional looms have been doing. But for centuries people have been using these types of looms and 80% of the workforce are females, and 60% of them are children. So we actually tried to "engineer out" the child labor from this [workforce], and we produced an adult-friendly ergonmic loom. By sitting on a bench, the adults don't face those musco-skeletal problems, the respiratory problems, and we have also included [other design elements]. Previously the looms were installed in a dark corner of the room, as these people only have one room homes. These looms are portable and can be used in sunlight or in the courtyard or anywhere they feel comfortable using them

|

| A child weaving |

What results have the improved looms had in the workforce with access to them?"

It has dramatically increased the health profiles of the families. We have compared a segment of the workforce who are using the new loom, 30 of them, versus those who were using the traditional ones, and there is a remarkable difference in the health profile. Those who are using the new looms, their problems with their back, joint pain, frequent allergies, and respiratory problems, are gone. At the same time their income has increased -- from 30-100%!

Why the income increase?

[Because] they are no longer using child labor anymore, the adults are working on them, [and they] are more skilled. Also, these new looms are placed in a [well-lit] environment, they can see what they are doing and are producing better quality carpets. At the same time, the old looms were owned by the contractors who were holding the family in debt. These looms AREN'T owned by the contractors, but by the families.

Are they rented?

At the moment we have them free of cost, but we are making arrangements wherein they can own them, without paying the intitial cost of the loom [upfront], but by paying it without interest and in very small installments.

How much do one of these looms cost?

Well in dollar terms, it's around $250, but there are a lot of associated health and safety and transportation costs, installation costs, and frequent visits. That makes it at about $450 per loom, which is around three times more than the traditional one, but one success indicator is that a lot of private entrepreneurs are copying it in their own processes.

If someone else wanted to take this design and market it, how would that work?

We intend to file it. Not for commercial purposes, but we intend to control the quality. We want to insure that good quality looms are there.

Now the traditional loom, you say that that design has been around for centuries?

Yes, very little has changed in the design. The posture has been the same over the centuries. People have [had] to sit on their toes and squat on the floor. [These looms are in use in] Pakistan, Nepal, India, Afghanistan, Iran... so this is a big problem. There are a half million looms in Pakistan right now. Each loom is worked on by 2-3 individuals at least, so that's at least a half million people.

|

| Quashqai women weaving a Gabbeh. |

How many of the new looms are out there right now?

Thirty of them at the moment, but for two years we were just testing them and how effective they are, and any problems [they might have].... then trying to promote as a business venture whereby people can own it. They are not indebted to anyone.

And how is the design more adult-friendly so the children can't use them?

One thing is the height. The kids can't sit with their legs dangling and at the same time do the knotting. With the adults they have a footrest and can work more efficiently on it. Children can't do more efficient work on this one. In the old one, they had to sit on the ground, working in a very cramped position.

Are you the engineer that came up with this design?

I came up with the design but I asked some people I knew [to help since] I am not a physical engineer, myself. I have a background in chemistry and occupational health. Being an occupational health professional I knew the problems, the ergonomic problems these people were facing, and what features the new loom should have. We hired engineers and some other professionals, along with the workers themselves... we tested many prototypes.

You are coming halfway around the world... what are your hopes here?

It's really an amazing thing that this has been recognized on an international level, on a global level. And I hope it will bring [about a change in] thinking that child labor can be combatted with very little input of capital, but more of an input of ideas in technology. That adults can actually be made to work, can take up the jobs that they are not taking up because of the poor wages and the poor health conditions that have their work. The International Labour Organization is now asking us to make similar kinds of models in other sectors where children are working in very hazardous conditions... so that gives us respect towards the work we have already done. .... This award will help in a big way, in promoting other areas.

What is your ultimate goal for your project?

In this particular project we hope that all looms, in Pakistan at least, so that the poor families, all of them can have the new one. But then I have other dreams that we should not be exploiting the [labor] conditions in other sectors. Even [a minimal amount of] input of technology can change the lives of the people who are held in that bondage... whole families are held, because productivity is so low and their wages are so low, they just incur debt. We want to promote these kind of models everywhere, where children and adults are working in very exploited conditions. We have already provided some assistance to Nepal... This is just the basis towards what we can do in the future.

Do you have any heroes?

My heroes are the children who are working in very difficult circumstances, who are supporting their families. I want these heroes to go to school, not to work on the very hazardous work they are doing, and I want to support their families in whichever way we can so they can disengage these children from hazardous work. I have seen these very tenacious people, very highly intelligent people, but unfortunately all their talents are being spoiled because we are not using their potential. We are wasting a huge potential of humanity. These people, when they grow as adults, they are not as useful to their societies, but I would still say they are my heroes, as they have enormous talent hidden in them.

Page created on 3/20/2013 2:28:09 PM

Last edited 1/5/2017 7:30:37 PM