REPRINTED WITH PERMISSION FROM THE CHRISTIAN SCIENCE MONITOR

Stacy Brown of Lafayette, Tennessee, polishes his motorcycle in advance of the Great Teddy Bear Run in Bowling Green, Kentucky, April 30, 2022. Until last year, repairing certain motorcycles oneself could compromise their warranty. Grace Ramey/Daily News/AP/File

Stacy Brown of Lafayette, Tennessee, polishes his motorcycle in advance of the Great Teddy Bear Run in Bowling Green, Kentucky, April 30, 2022. Until last year, repairing certain motorcycles oneself could compromise their warranty. Grace Ramey/Daily News/AP/File

March 13, 2023

Going back almost as far as he can recall, Ronnie Partridge took broken things and made them whole.

“I found stuff on the side of the road, and took it back to the house and made it work again. That’s how it all started,” says Mr. Partridge, who owns Ronnie’s Small Engine Repair here on the edge of Beaufort National Cemetery, deep in South Carolina Lowcountry.

A local mechanic hired him when he was 15 and, 10 years later, the student became the master. At the time, Mr. Partridge couldn’t afford to buy the shop. But the owner, upon retirement, gave him his collection of tools – many of which are still lying around his workshop, which he has owned for decades now.

Mr. Partridge says fixing stuff has always engaged his brain, but also calmed his soul. His admittedly “messy” workshop is a wonderland of parts and broken skeletons of lawn mowers past. Amid the tangle, he has the air of a grease-smeared monk – content with a knowledge that almost anything is fixable.

His is a thoroughly American story, woven throughout with self-determination, willpower, and an indomitable can-do attitude.

But today Mr. Partridge’s rise seems increasingly improbable: Fix-it shops have been in steady decline. RadioShack is gone from the mall. The corner camera shop is largely no more. Even longtime car mechanics have begun to throw in the shop towel as auto manufacturers make it increasingly difficult to fix their new models.

Melanie Stetson Freeman/StaffScott Spindler (left) and his twin brother, Derek, repair vacuum cleaners at Mr. Sweeper Sales and Repairs, a family-owned business, on Feb. 21, 2023, in the West Roxbury neighborhood of Boston.

Melanie Stetson Freeman/StaffScott Spindler (left) and his twin brother, Derek, repair vacuum cleaners at Mr. Sweeper Sales and Repairs, a family-owned business, on Feb. 21, 2023, in the West Roxbury neighborhood of Boston.

And corporations now retain stakes in the software driving their products, further complicating the repair landscape. As Wilmington Island, Georgia, computer technician Jim Moore puts it: “What do you own? Nothing. You own the plastic, that’s it.”

With consumers loath to pay more than 20% of replacement cost to repair something, analysts say, corporations can set pricing at a point that encourages customers just to buy a new unit. That not only squeezes independent repair shops but generates unnecessary waste. It also reduces the likelihood that tinkering will inspire innovation.

But people are beginning to push back.

Here at Mr. Partridge’s workbench – laid with strips of recycled tire – there is a feeling that this sliding sense of ownership, the cheapening of quality, and a relentless focus on consumer experience over meditative tinkering matter to the nation more broadly.

By Mr. Partridge’s side stands his 20-something son-in-law and partner, Jarrett Lavender. Mr. Lavender sees himself, in some ways, as the future of American tinkering. But he says that America needs a refresher course in how things work – in order to get things fixed.

“I think we need to go back to some olden days,” says Mr. Lavender.

Moon shots, World War II mobilization, the computer, the Manhattan Project – many influential inventions, used for good and ill, sprang in part from the impulse to take stuff apart and put it back together again, maybe a little differently. The U.S. Constitution is basically a fix-as-you-go manual for democracy.

As U.S. Rep. Marie Gluesenkamp Perez, a former auto shop co-owner from Washington state, has said: “DIY is in our DNA.”

Corynne McSherry, legal director for the Electronic Frontier Foundation, headquartered in San Francisco, concurs. “In the United States, we’re a nation of inventors, a nation of innovators,” she says. “We don’t want to just be recipients of technology.”

Courtesy of Jessa JonesJessa Jones makes microsoldering repairs at iPad Rehab near Rochester, New York.

Courtesy of Jessa JonesJessa Jones makes microsoldering repairs at iPad Rehab near Rochester, New York.

Less waste, more innovation

Two points loom large in the right-to-repair discussion: reducing waste and the Americanness of tinkering.

In 2019, Americans sloughed off more than 45 pounds of metal-ridden hazardous electronic-waste per person, according to The Global E-Waste Statistics Partnership.

“We have really been coached and coaxed over the last 40 or 50 years to not think like our parents or grandparents thought, which is, you buy something and your goal is ... to keep it functional as long as you can,” says Paul Roberts, the founder of SecuRepairs, a citizen group that advocates for the right to repair. Instead, “we have been coached to think that ... it’s cheaper” to replace it and pitch the old one, he says. “But it isn’t cheaper.”

“If a 50-cent capacitor fails on your printer’s circuit board, it’s not cheaper to buy a $120 new printer and create 20 pounds of e-waste,” he adds. “It’s cheaper to keep the damn printer working.”

At its heart, though, the right to repair is about fundamentally American ideas – being able not just to control and tinker with what you own, but to stumble onto new ideas and create new products.

“You really need to be able to take your things apart to understand [them], to make [them] better,” says Ms. McSherry. “If we don’t have that ability ... it becomes harder to have add-on innovation and competition.”

In 2021, the U.S. slipped out of the top 10 in the Bloomberg Innovation Index – after leading the initial ranking 10 years ago. Many factors come into play, of course, but some argue that less physical innovation and more focus on customer experience is partially responsible.

Yes, it’s hard to prove. But less tinkering, some critics say, could mean less progress.

“It’d be nice if there were a way to test the theory that not having repairable items drains the ingenuity of the population,” says Bill Sheehan, one of the founders of the “zero waste” movement in the 1990s. “The whole game these days to get rich is to make better widgets and then [get] bought out by one of these billionaires.”

Alfredo Sosa/StaffShop manager Carlin Anderson repairs a bicycle at Blackstone Bicycles on Feb. 17, 2023, in Cumberland, Rhode Island.

Alfredo Sosa/StaffShop manager Carlin Anderson repairs a bicycle at Blackstone Bicycles on Feb. 17, 2023, in Cumberland, Rhode Island.

“Ingenuity as an American value”

Like many tinkerers, Adam Savage discovered the wonder of deconstruction and reconstruction in a bike shop, in his case Sleepy Hollow Bikes. Constantly on the move, his tires kept busting. Finally, the shop owner took him aside and said, in essence, “Let me just show you how to do it.”

Fixing flats was just the beginning. At 19, Mr. Savage gave up a budding acting career – he played the stock boy Jimmy in the “Don’t squeeze the Charmin” commercials – and began working on special effects for films like “Galaxy Quest” and “The Matrix” sequels.

That work led to being hired as the co-host of a popular Discovery Channel show named “MythBusters.” With his co-host, the taciturn and mustachioed Jamie Hyneman, Mr. Savage took on challenges to test the truth of urban myths.

That required utilizing things in ways that were never intended. The mystery of whether tinkering would pay off provided the tension in the show, and proved to be deeply satisfying to viewers. The hosts’ mediums ranged from metal to plastic, rubber to plaster, and required pneumatics, mold-making, and injection molding – not to mention explosives.

With 284 regular episodes and dozens of specials, the show went through 83 miles of duct tape.

It is “absolutely right when we talk about ingenuity as an American value, at least within the story that America tells itself,” says Mr. Savage. “I don’t have an issue with capitalism per se, but the rent-seeking that companies now are attempting to do ... is completely anathema to that spirit of ingenuity,” he adds, citing BMW’s subscription service for premium features such as heated seats.

Same problem, different answers

The groundwork for subscription add-ons was laid in the 1996 Digital Millennium Copyright Act. Established to thwart software piracy, it gave wide berth to corporations to keep control of their intellectual property. One way that can be done is by requiring features to be unlocked through purchases. That type of rental agreement turned out to be quite profitable.

Danny Wood learned that the hard way. A former tractor mechanic, he now grows wheat in Peetz, Colorado, and loves the new technology that companies like John Deere make available.

“The new tractor is so amazing,” says Mr. Wood. “You can set your speed, put it in gear, and it takes off. It puts the engine to optimal engine RPM.” Along with GPS technology, which increases the efficiency of the combine, “that tractor is the most wonderful thing in the world.”

Seth Perlman/AP/FileManufacturer John Deere has agreed to provide farmers the tools needed to repair their equipment.

Seth Perlman/AP/FileManufacturer John Deere has agreed to provide farmers the tools needed to repair their equipment.

Yet he has more than one example of equipment breaking down, leaving the machine “sitting at the edge of the field for days” for what turned out to be simple, but very expensive, fixes. The experiences left him lobbying for a right to repair bill in Denver in February.

“I don’t expect John Deere or Case to give us all their proprietary information,” he says. “They spend tens of millions of dollars on their engineers to design these control systems. At the same time, they’ve got us handcuffed. They own the internal workings of that tractor, and if they want to, they can shut it off. So, what the hell did we buy? The right to beg them to let us use their stuff?”

To him, it seems an untenable situation, given the nature of farming – part of which is the knowledge and ingenuity to keep the tractors running when harvest is nigh.

Just this year, however, on Jan. 8, an agreement was reached between John Deere and the American Farm Bureau Federation that gives farmers, ranchers, and mechanics access to Deere’s diagnostic software and tools – for a fee.

But by then, Walter Schweitzer, who raises beef cattle near Geyser, Montana, had already chosen a different solution.

“Farmers love technology,” he says. But when his equipment broke down and it became clear that the repair would be far costlier than if he could tackle the job himself, he grew angry. Then, he took action.

Last year, Mr. Schweitzer lobbied for a right-to-repair bill, which failed, he says, after industry lobbyists parachuted into Helena to fight it. They claimed the legislation was repetitive and could leave techs out of work and farmers worse off.

So Mr. Schweitzer did what many of his fellow farmers are doing. He bought a 25-year-old tractor. When a transmission light blared, he found a $40 part and spent two hours in the barn fixing it himself.

“A lot of people are now trading in their new tractors for older ones,” he says.

But just as buying new electronic devices instead of repairing older ones contributes to e-waste, purchasing old machines so that you can easily repair them is usually a backward step in terms of energy efficiency, putting right-to-repair advocates on the defensive.

J. Scott Applewhite/APMarie Gluesenkamp Perez joins new members of the House of Representatives on the steps of the Capitol, Nov. 15, 2022.

J. Scott Applewhite/APMarie Gluesenkamp Perez joins new members of the House of Representatives on the steps of the Capitol, Nov. 15, 2022.

Potential downsides: Pricing and pollution

In winning a Republican-leaning district in the state of Washington, in what many saw as a stunning upset last November, Representative Gluesenkamp Perez credited her background as a fixer, a member of “the trade.” Then, in January, the Democrat co-sponsored a bill that would guarantee consumers access to data, critical repair information, and tools to let them fix their own cars.

It is a popular idea, on its face: Nearly 7 of 10 Americans support a basic right to repair, according to a 2022 Morning Consult poll. And since 2014, more than 40 states have begun considering some type of right-to-repair bill, The Repair Association, an advocacy trade group, reports on its website. Maine voters will decide on a referendum on the issue later this year.

“Success will be creating laws that enable your neighbor to start a little business on your Main Street to do that stuff,” says Mr. Roberts of SecuRepairs. “You call Jim or Susan to do the diagnosis and fix it. Save the planet and save your wallet, all while creating wealth in our society.”

Yet opposition is mounting, supported in part by research suggesting that comprehensive right-to-repair laws will have negative effects on consumer prices and environmental protection.

For cheap-to-manufacture products like smartphones, researchers say corporations will simply drop prices, leading consumers to purchase new models and turn their old ones into e-waste.

Steven Senne/AP/FileBrian Hohmann, mechanic and owner of Accurate Automotive, in Burlington, Massachusetts, attaches a diagnostics scan tool to a vehicle and a laptop, Feb. 1, 2022, in Burlington.

Steven Senne/AP/FileBrian Hohmann, mechanic and owner of Accurate Automotive, in Burlington, Massachusetts, attaches a diagnostics scan tool to a vehicle and a laptop, Feb. 1, 2022, in Burlington.

For high-cost durable goods, “manufacturers may raise prices, and with a flourishing repair market, more people might end up buying and using old power guzzlers,” Luyi Yang, Chen Jin, and Cungen Zhu write in a January Harvard Business Review article. “All told, a right-to-repair bill in this scenario can create a ‘lose-lose-lose’ situation that compromises manufacturer profit, reduces consumer surplus, and exacerbates the environmental impact despite repair being made easier and more affordable.”

Those arguments are powerful: The vast majority of right-to-repair bills so far have failed, in part out of legislators’ concern about the effects on manufacturers.

In some cases, though, urgent, personal repair needs can influence public policy.

Fixing phones, wheelchairs – and lives

For Jessa Jones, it started with unbolting her toilet, bringing it into the front yard, and smashing it with a sledgehammer, while neighbors watched in awe, her company website explains.

From the shards, she retrieved an iPhone flushed away by her twin daughters. Using the research skills gained from her Ph.D. in molecular genetics, Dr. Jones, who was then a stay-at-home mom, became hyperfocused on salvaging the phone’s photos, even though repair shops said it was impossible. It took her two years and a dining room filled with microscopes and soldering stations, but she did it. And what she learned about troubleshooting iPhone logic boards is now a business called iPad Rehab, employing seven former stay-at-home moms and one stay-at-home dad in Honeoye Falls, New York.

Fans call her “Jessa the Professa.” Her microsoldering company proved that what many Americans think is “magic,” as Mr. Roberts puts it, is actually fixable with a microscope, a special soldering iron, and an inquisitive mind.

Dr. Jones’ lobbying helped lay the foundation for the comprehensive New York right-to-repair law signed by Democratic Gov. Kathy Hochul in December. Both Samsung and Apple have promised to make proprietary tools and diagnostics available to consumers. Dr. Jones supports the law, but the final version gives manufacturers more rights than she had hoped for, she told The Grist.

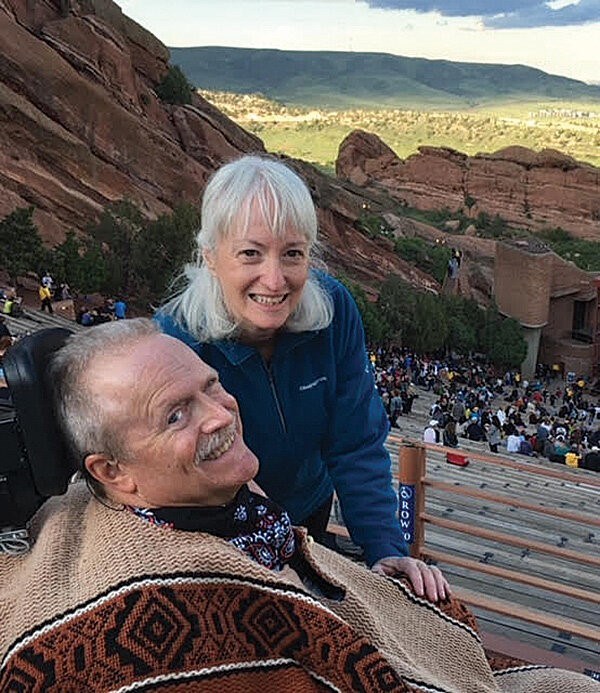

Courtesy of Robin Bolduc and Bruce GoguenRobin Bolduc (right) and her husband, Bruce Goguen, attend an event at Red Rocks Park and Amphitheatre in Morrison, Colorado.

Courtesy of Robin Bolduc and Bruce GoguenRobin Bolduc (right) and her husband, Bruce Goguen, attend an event at Red Rocks Park and Amphitheatre in Morrison, Colorado.

In Bloomfield, Colorado, Robin Bolduc makes no claims to have Dr. Jones’ tinkering abilities. But she does have a lot of experience fixing public policy. Ms. Bolduc met her husband, Bruce Goguen, at a protest over disability access.

Funded in large part by Medicaid, the billion-dollar motorized wheelchair market in the U.S. is led by a few large companies, often owned by private equity firms that have bought out local stores or simply put them out of business. These large corporations can bolster profits by cutting spending, including limiting the number of technicians and available parts, which leads to slowdowns in repairs.

Mr. Goguen felt that slowdown firsthand. He operates a wheelchair with a special button that allows him to navigate using his head. It broke. When Ms. Bolduc called the manufacturer, they said the back-ordered part could take months to arrive.

But for Mr. Goguen, using the wheelchair isn’t just a matter of mobility. “He could literally die” if he is stuck in bed because he doesn’t have a functioning chair, says Ms. Bolduc.

Frustrated by the lack of urgency in the company’s response, Ms. Bolduc scoured the internet and found the part – for $20. She fretted about being able to install it, but it turned out to be just a simple plug-in, like a cellphone charger. Such repairs, however, run the risk of voiding warranties and aren’t eligible for insurance reimbursement. Also, Medicaid doesn’t cover preventive maintenance – the kind users can do themselves, like tightening screws. That’s true even when, in cases like Mr. Goguen’s, the wheelchair isn’t leased; he owns it. And when wheelchairs aren’t routinely maintained, breakdowns, when they happen, can be more serious.

As their frustrations rose, the couple, both of whom are members of the Colorado Cross-Disability Coalition, took action. Ms. Bolduc’s efforts at the statehouse powered a first-of-its-kind wheelchair repair bill passed by the Colorado legislature last year and signed by Democratic Gov. Jared Polis. When it took effect in January, the company, Pride Mobility, gave the couple a proprietary tool they can use to adjust the wheelchair.

That gracious gesture, once the law took effect, underscores one way forward, says Ms. Bolduc.

Profits are one thing, but companies also want protection. After all, without a right-to-repair law in place, handing a proprietary tool to an inexperienced user could sink a firm into legal jeopardy if something were to go wrong. But people with disabilities, says Ms. Bolduc, aren’t interested in hacking and controlling a chair.

They just want cheap, quick, and, if possible, easy fixes. To many Americans, she says, that could be a selling point.

“I’m hoping we’re not an anomaly, that what happened to us is where it’s going to go: that companies will embrace a new market and a new way to market themselves,” she says.

Back in Beaufort, Messrs. Partridge and Lavender say they are busier than ever, thanks, in part, to the fact that companies are making ever-cheaper products – in many cases, replacing hardy metal parts with easy-to-break plastic ones.

But for them, repair isn’t just about gears and grease. Mr. Lavender was never particularly mechanically inclined. But after he endured a “rough patch in my life,” Mr. Partridge showed him the basics of repair.

“He picked me up and helped me and got my life turned around,” says Mr. Lavender. “Ronnie fixed things up pretty good.”

Editor’s note: This story was first published online on Feb. 6, 2023. This version was expanded for print and featured as the cover story in the March 20 edition of the Monitor Weekly.

Related stories

Page created on 3/17/2023 10:28:28 AM

Last edited 3/17/2023 10:46:04 AM